Aluminium, an exceptional material

Easily malleable, aluminium is used in a multitude of products and applications that take advantage of its unequalled characteristics of lightness and durability.

A green material par excellence – aluminium can be recycled ad infinitum – it is the obvious choice for clients who are concerned about the environment and sustainable development. Its lightness and robustness improve the energy efficiency of rolling stock, while its longevity reduces the total cost of ownership of the infrastructure that incorporates it.

Aluminium is available from Alliance Connect who offer a range of aluminium products and alloys.

Hundreds of processors shape the metal to suit the needs of the customer-user. Forming processes such as extrusion, forging or casting shape the metal into the required form. The processed aluminium can then be machined, precision cut and bent into any shape.

It is also possible to treat its surface and assemble several parts to create structures of any size. Finally, the various alloys improve its mechanical properties, including durability, malleability and corrosion resistance. The possibilities are endless!

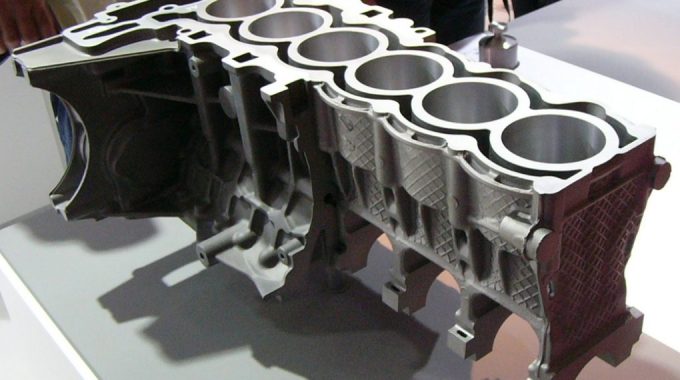

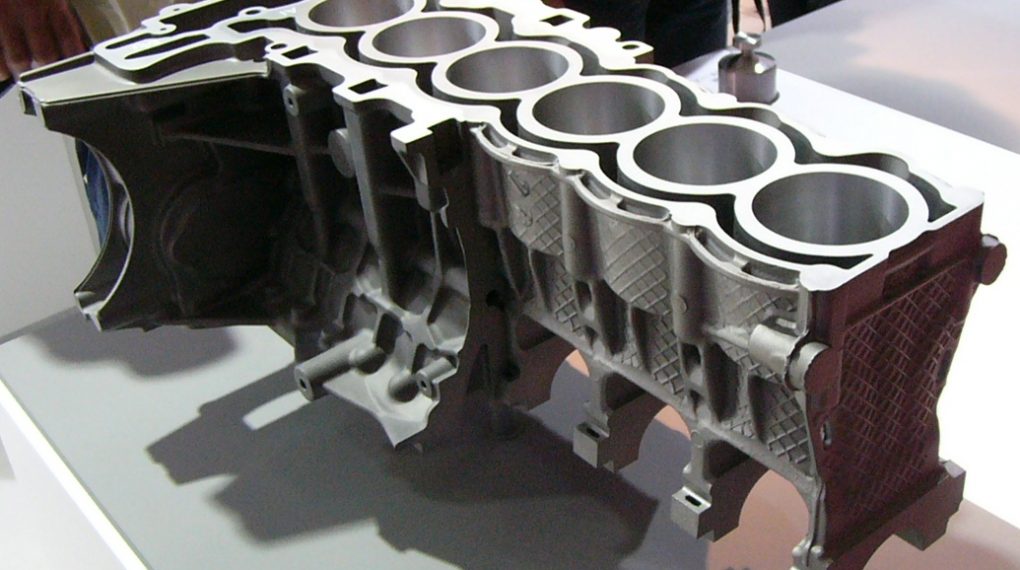

Let’s take a look at a high-pressure die casting

Aluminium alloy die casting is a universal means of obtaining constructed metal parts by pressing a molten aluminium alloy at high pressure into reusable steel moulds. These forms can be intended to produce complex products with a high degree of precision and for mass production.

Advantages of manufacturing by die casting

– High production speed: possibility to produce large series of castings with minimal mechanical modification or a fully finished product

– Dimensional accuracy and stability, adherence to tolerances throughout production, even for colossal series

– Durability and weight: compared to other casting methods, we can achieve lightweight, thin-walled castings with a high degree of complexity, surface cleanliness, strength due to solidity and the absence of casting shells

– High-pressure die-cast products require minimal preparation before galvanic treatment

Castings weighing 5 grams to 12 kg can be produced in a die casting shop. For zinc alloy parts, hot chamber die casting equipment is used. This is necessary because the melting temperature of zinc alloys reaches 900 degrees Celsius. If cold chamber die casting equipment is used for these alloys, the tooling will be exposed to large temperature drops, and its life will be considerably reduced. Cold chamber die casting equipment is generally used for casting aluminium and magnesium alloys.

Although these types of castings have many advantages (high production speed, high precision of the obtained products, high strength, surface cleanliness of the obtained products), one crucial disadvantage can be said – the high cost of the tooling.

Manufacturing of steel and cast iron chill casting

In the chill casting process, the molten metal is poured into a disposable thin-walled mould made by applying a mixture of sand and resins to the required product’s pattern (the so-called mould).

The pattern is reusable and allows you to form several shell shapes.

Reusable patterns allow you to increase production rates while obtaining more geometrically complex and precise products with disposable designs.

Chill casting typically uses black and non-ferrous metals, most commonly carbon steels, cast iron, alloy and stainless steels, aluminium alloys and copper.

Chill casting is thus very much in demand for:

– Tractor parts and agricultural equipment parts

– Pump bodies and rotors

– Machine tool parts

– Parts for the oil and gas industry

– Bearing housings

– Electrical equipment parts

– Parts for the mining industry

The most common products obtained with this moulding are medium-sized and high-precision products, such as gears and pinions, casings, cylinder heads, connecting rods, levers, etc.

Read more: