If you’ve ever held a finely crafted object in your hands, chances are it has gone through a meticulous process known as casting and finishing. In Australia and New Zealand, a wide array of casting and finishing services cater to various industries, bringing life to intricate designs and ensuring the highest quality of products. In…

What Are the Advantages of Die-Casting? Die-casting is a manufacturing process in which molten metal is poured or fed into steel moulds. The moulds, also known as dies and tooling, are created from steel and are specially designed for each project. This allows each component to be made with precision and repeatability. Aluminium, zinc and…

Aluminium, an exceptional material Easily malleable, aluminium is used in a multitude of products and applications that take advantage of its unequalled characteristics of lightness and durability. A green material par excellence – aluminium can be recycled ad infinitum – it is the obvious choice for clients who are concerned about the environment and sustainable…

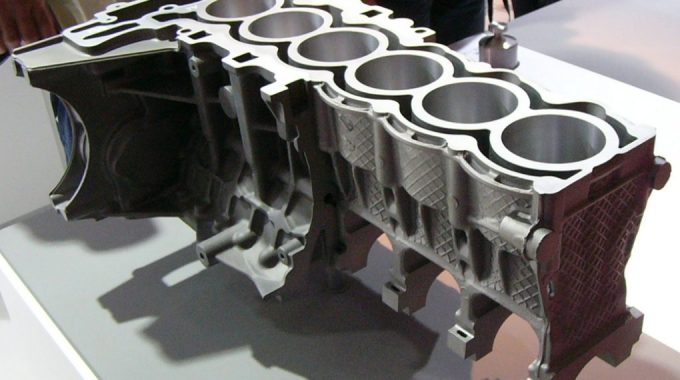

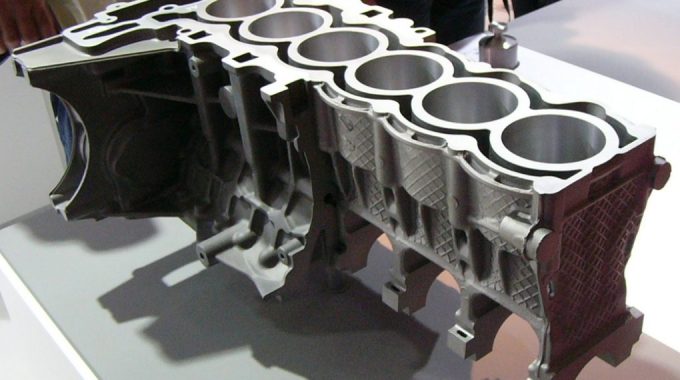

A Guide to Die-Casting Technology Die-casting allows the production of near-net-shape parts in large series at relatively low costs and benefits from a high degree of automation of the production sites. It is dedicated to transforming parts made of non-ferrous alloys (aluminium, zinc, copper, magnesium, etc.) for various markets (automotive, household appliances, construction, etc.). The…

Summary: Introduction 1. Traditional Die Casting 2. Vacuum die casting – Alloys for die-casting – Alliance Connect (offering the die casting process) 3. Semi-solid die casting Introduction The low melting point of aluminium allows the use of a permanent mould, made of steel, to make castings. In die-casting, an injection piston pushes the liquid aluminium…