Laser cutting is a digital subtractive technique that uses laser technology to cut or engrave a variety of materials using a laser. So, without further ado, let’s dive into this blog and learn some things you need to know about laser cutting.

1. History

In 1967, Peter Houldcroft of the Welding Institute in Cambridge developed a cutting nozzle with an oxygen pump and cut a sheet of steel. Things progressed rapidly, and in 1969, a trio of engineers from Boeing wrote a paper on how to build a laser cutting machine to cut harder materials, and less than a year later, the first laser cutting machine tool was built in Scotland.

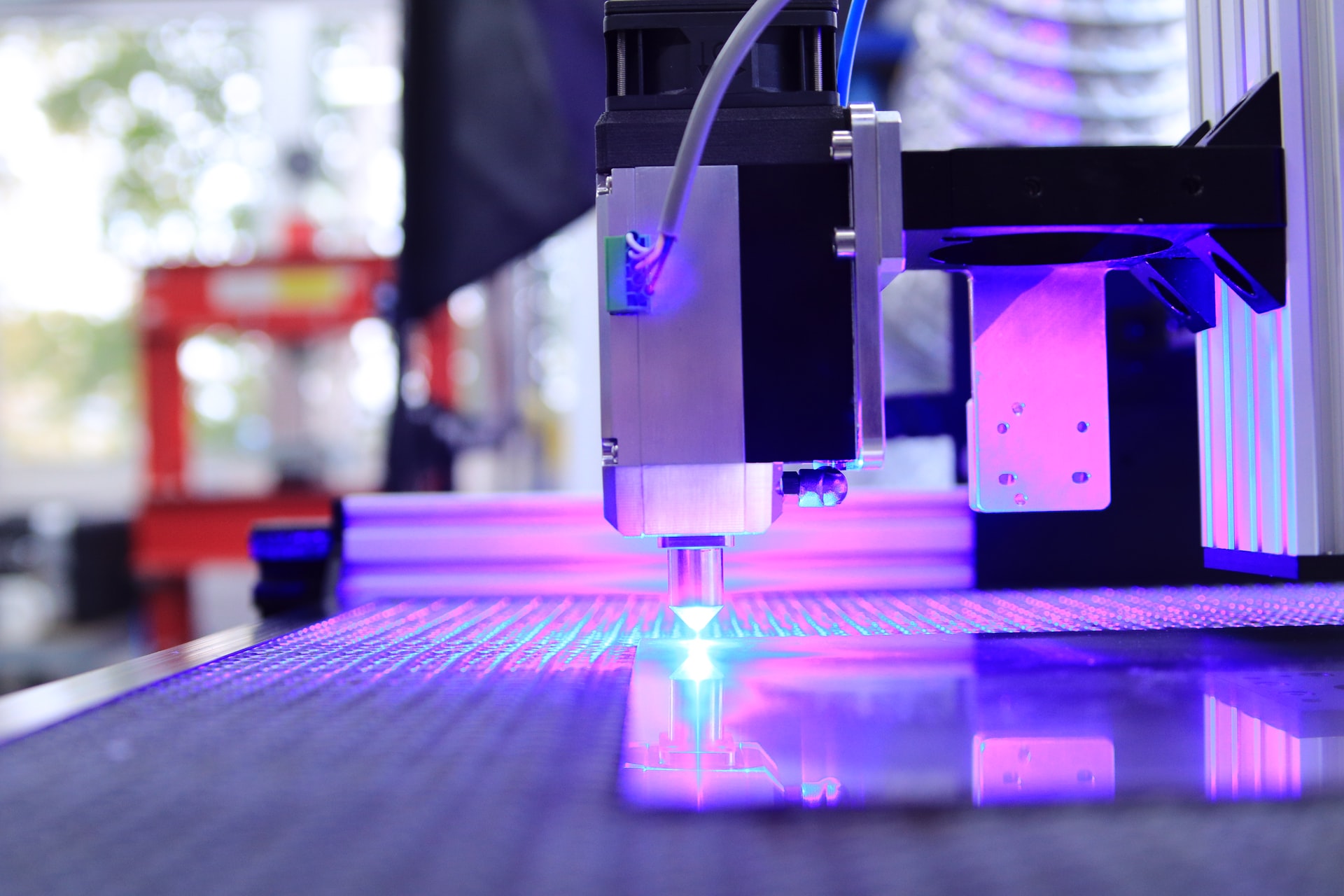

2. What is laser cutting, and how does it work?

Widely adopted in the industrial manufacturing sector, laser cutting is gaining ground in small establishments such as schools and small businesses, as well as among hobbyists. The laser power of this machine is directed by optics and a computer numerical control. This allows the material to be shaped. It is enough to enter the CNC or G code of the design you want to materialize on the material. The laser beam burns, melts, or sprays the material with a gas jet to produce high-quality finishes.

-

- For wood: It applies a lot of precision and detail for small parts ideal for plywood

-

- For plastic: it is fast and accurate and has city corners and stops

-

- For glass: it is the easiest technique to cut glass

-

- For metal: this is the cleanest and most accurate metal-cutting technique. The result is precise and well-cut.

3. What can be cut with a laser?

A laser cutter is gaining momentum in factories and industries that use it to make precision cuts and clean cuts. Even though it is gaining popularity, it is important to know what materials can be cut with a laser and what types of work can be done with it. Here is a list of some of the materials that can be cut with a laser:

-

- Wood: raw wood, MDF, and plywood. It is not recommended to laser-cut thicker wood boards.

-

- Metal: the precision of the laser cutter allows for complex and custom designs. We use it for unique and personalized designs by our customers.

-

- Some plastics: polyurethane, polyethylene, polypropylene, polystyrene, acrylonitrile, polyester, and polyamide…

-

- Aluminum: it is soft, light, durable, and easy to cut on a laser cutter. However, since aluminum is a reflective material, it is important to cover it when cutting it to prevent the reflective light from damaging the laser. However, it is dangerous to use laser cutters on materials whose composition consists of chlorine, fluorine, or any other toxic gas; on reflective materials that can damage the machine. In this case, you should use fiber laser cutting; on Valchromat, for example, because there is a high chance of burning and melting. To avoid destroying your material, check the composition of the material to make sure it is compatible.

4. What are the types of laser cutting?

There are two types of laser cutting. It is necessary to distinguish between them in order to choose the right tool for the job.

-

- Diode laser cutters These machines are ideal for engraving and marking because they are less powerful than a CO2 laser cutter. They are used on thin and softwoods. These lasers come in red (the weakest), green (higher power than the red laser), and blue (very high power and can blind the human eye).

-

- CO2 laser cutters These laser cutters come in several sizes and are ideal for cutting with remarkable precision. Its laser uses infrared light to make cuts.

5. How much does laser cutting cost?

The cost of laser cutting varies according to certain criteria:

-

- The desired design: the more complex the model to be made, the more it is possible for the price of the service to increase.

-

- The thickness and type of material: thicker materials tend to require more energy from the machine than thinner materials. Also, there are materials that are much more delicate and others that are more resistant. For example, the cost of cutting aluminum plates to size is high because it is an extremely reflective material.

-

- The number of materials to be cut: depending on the quantity of materials to be cut, the price will increase.

Looking for help?

Are you in Melbourne? Are you looking for a laser-cutting company? Then look no further because Dennis Welding and Fabrication is here to help you out with all your needs. They are the leaders in industrial metal works in Australia. They offer a wide range of services, including custom metal fabrication and repair, welding fabrication and repair, plasma cutting, sheet metal fabrication, sandblasting, industrial furniture fabrication, table legs, TV stands, and more.

Equipped with the latest technology and materials, our highly skilled team is able to deliver services seamlessly to the highest standards. Rest assured, they can handle any project regardless of size or scope. They serve clients throughout Melbourne, Box Hill, and Thomastown. So, what are you waiting for? Give them a call today to learn more about their wide range of services.