There are a wide variety of studio effects, some of which are indispensable for recording. The compressor, for example, is the most common audio processing tool used by the general public. It can take the form of a software program or an actual device. But what exactly is a compressor? What does it do, and how can you use it? So, without further ado, let’s dive into this blog and learn some of the things you need to know about compressors.

1. How much power do you need?

The amount of power you need depends on the type of tools you have and/or how much you use your compressor:

- If you only need a compressor for activities that require occasional use, such as blowing, nailing, inflating, varnishing, or spraying water, choose a direct-drive compressor. As a rule of thumb, a compressor between 1.5 and 3 HP with an air capacity between 10 and 20 m3/h should be sufficient.

- Applications such as washing, sanding, professional blowing, professional painting, and ratchet chipping generally require a capacity of 12 to 30 m3/h. In this case, it is best to choose a single-stage compressor with a power range between 2 and 4 HP. These compressors are suitable for frequent use.

- And for more demanding applications, such as professional service and installation, body repair, torque, or dry air applications, look for tools with capacities between 30 and 150 m3/h. A two-stage compressor provides these high flow rates with more than 4 HP. Also consider this type of compressor if the frequency of use is high.

2. How do I determine my compressor’s horsepower and flow capacity?

Check the power and volume requirements of your tools. Heavy tools require a lot more pressure and, therefore, more volume. Add up the horsepower (m3/hr) for the tools you will be using at the same time, then add 35% as a safety margin.

This margin will give you the maximum required usage of liters per minute that you will need. When choosing your power, you will want to optimize this power to minimize the time and cost of operation. If you are working with more than one person at a time, consider the simultaneous use of tools in your calculations.

3. How big should the container be?

Tanks or containers are measured in liters and are available in a wide range of sizes, from 6 to 500 liters. The choice and size of the container will depend greatly on how long you will be using your air tools:

- Do you just need a compressor for a short period of time? Choose a small tank. We recommend a size between 6 and 20 liters.

- Do you need a compressor for continuous work? If so, a larger tank will make your job easier. Choose a tank size between 20 and 90 liters.

- If you need it for professional use, we recommend a larger size, from 90 to 500 liters.

In order to check if the size of your tank is sufficient, you have to multiply the size of the container (in liters) by the amount of pressure (in bars). This value must be lower than the total volume required, including the safety margin (l/min). If it is higher, you need to increase the size of the tank. To calculate the volume in l/min, multiply the volume in m3/h by 16.67.

4. Do you need portable and movable equipment?

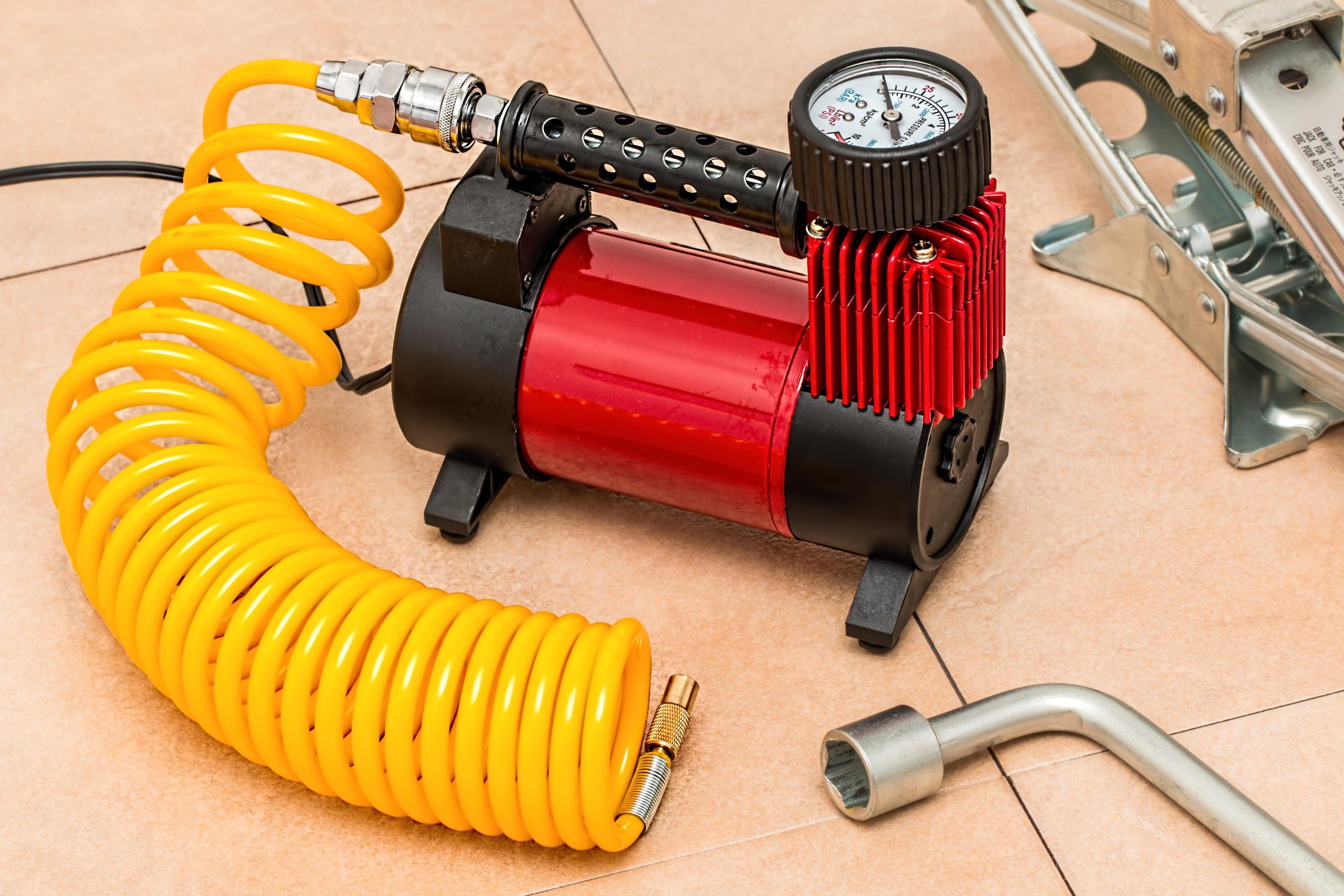

Having portable equipment can still be convenient, as these models are often light and easy to carry, but they will only be effective for small jobs such as tire inflation or airbrushing. You can also choose mobile equipment. These compressors are easy to maneuver with their rubber wheels and guide rollers.

Handles make it convenient for transport. In other cases, where the compressor use requires continuous use, mobility will not be advantageous, and a stationary compressor may be your best choice. In addition to the likelihood, the size of the compressor can also be important, provided you don’t have a lot of space. When space is an issue, choosing a compact model in which the vessel is positioned vertically is best.

5. Do you find that a compressor makes too much noise?

Does the fairly consistent noise of piston air compressors annoy you? You can choose compressors with special sound insulation. These compressors are extremely quiet and can be placed in the same room as the one you are working in or can be used for applications where silence is required.

Looking for help?

Contact Promptair & Electrical Pty Ltd for all your commercial and industrial maintenance and supply of air compressors, dryer, and even air filtration services. With Over 40 years in the field, trust their team to maintain and install your air compressors and accessories.

So, for all your compressed air piping needs, get in touch with an expert and let them help you with all your professional development needs. When it comes to compressed air piping, it is always better to call a professional instead of trying to do this yourself. So what are you waiting for? Give them a call for more information.