The air compressor is a do-it-yourself tool that can be used in many circumstances. It can be used for anything from simple pneumatic inflation to painting, drilling, or gluing. There are many different types of air compressors, but the important thing is to know how they work and to make your choice based on why you want to use them. So without further ado, let’s dive into this blog and learn about some of the best air compressors on the market.

How does it work?

The main function of an air compressor is to produce compressed air to run various DIY tools. To do this, a compressor consists of a motor that can be either electric or thermal. This motor will turn a cylinder which will compress the air in a sealed tank. When the air pressure is sufficient, the motor stops working. The motor and cylinder are called compression units. The compressor can be used to power a variety of tools such as a chisel hammer, stapler, nail gun, paint gun, sealant gun, impact wrench…

Two steps are important in the operation of an air compressor. First, the pressurization consists in compressing the air, which will make bounce molecules the ones on the others escape in the atmosphere. The compression will store energy. When this energy is released, the tool will work. The release of energy will be faster if a large amount of air is trapped in the tank, as this raises the air pressure.

Then, the depressurization, that is, when the pressure in the tank decreases, the gas molecules are also released little by little. The operation of a compressor is based on the airflow it delivers. This is measured in m 3/h. In addition, the volume of the vessel will indicate the air flow rate as well as the speed of the compressor.

The air compressor has various safety devices essential for its proper operation. It is equipped with a switch called the pressure switch. As soon as the pressure drops, it will restart the motor. The pressure regulator allows regulating the pressure to be released. Its function is to protect all the accessories. There is also the pressure gauge which indicates the pressure of the tank. It can be with a needle or digital.

The pressure gauge is used to control the settings in general. The safety valve is essential in case the regulator or the pressure switch has problems. This valve opens to release the air, preventing the tank from over-inflating or exploding. Finally, a compressor has a direct outlet where the maximum compression of the compressor is located. This is an auxiliary air intake that is not connected to the regulator.

Types of compressors

There are three main types of air compressors: the single-cylinder compressor, the twin-cylinder compressor, and a portable compressor.

1. The Single-Cylinder Compressor

As the name implies, the single-cylinder compressor consists of a motor that operates a single cylinder. It has a capacity to deliver up to 40m3/h of compressed air at a pressure of about 8 bars. Its power varies from 1.5 HP to 6.5 HP, with a tank volume of 25 to 250 liters. For this type, the tank is fixed on a frame that allows an easy displacement or also fixed on wall support to feed a pneumatic network. These are the most commonly used compressors because they can be adapted to long-term work.

2. The twin-cylinder compressor

The twin-cylinder compressor has a large capacity and high power suitable for compressed air supply. It consists mainly of a motor that operates several cylinders. In contrast to the single cylinder, it has a minimum power of 5.5 HP. It can deliver an airflow of more than 40m3/h, which can increase the pressure up to 13 bars. Generally, this type of compressor is intended for professional use. It is mainly used in paint shops, body shops, or mechanical shops.

3. The portable compressor

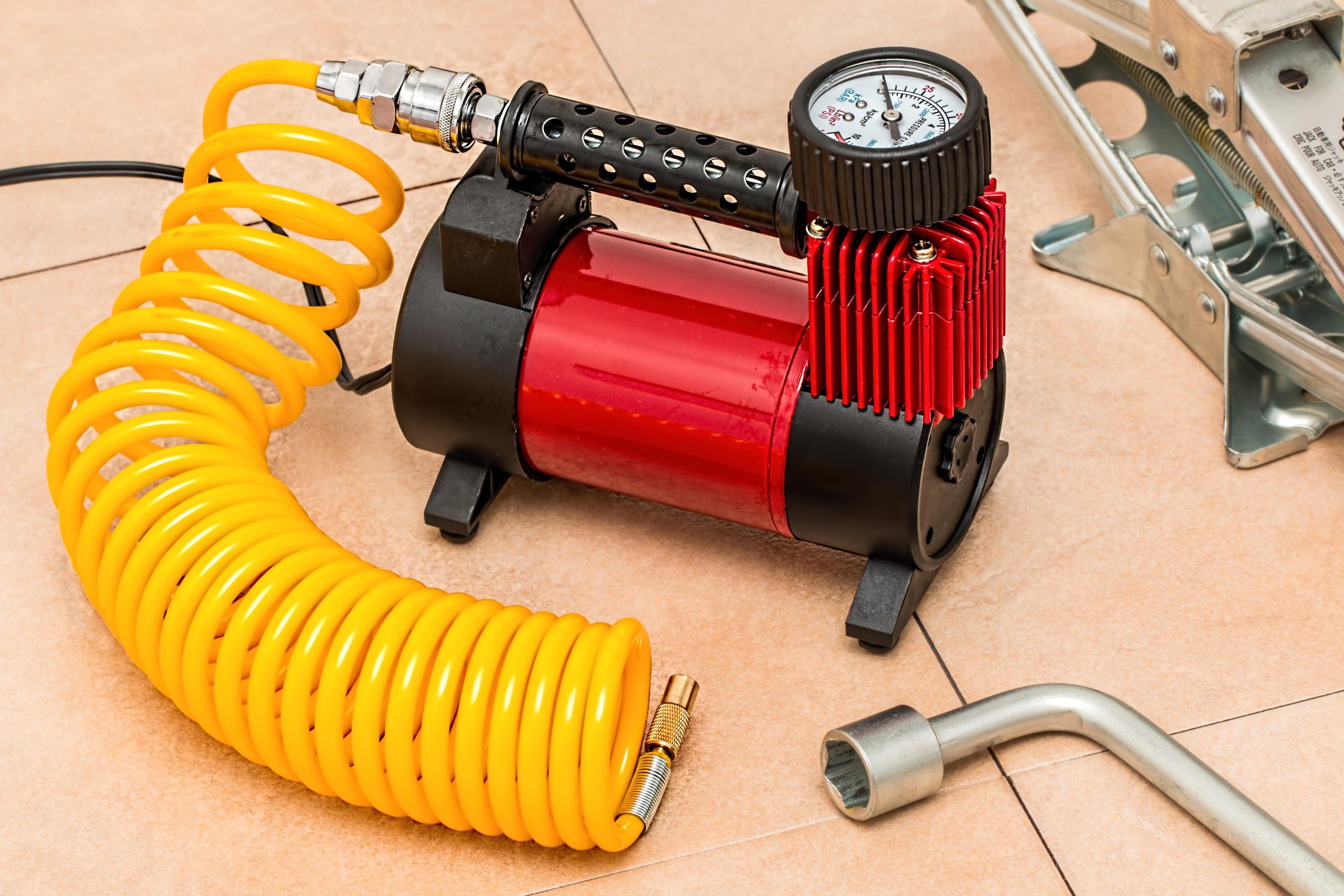

The portable compressor is the smallest form of compressor available. It has a tank capacity of less than 20 liters. There are even portable compressors that do not have a tank and weigh only 4 kg. It has a maximum power of 1,5 HP with a maximum airflow of 8m3/h.

This type of compressor is especially suitable for small jobs like inflating a tire or gluing and stapling something. This type of compressor is perfect for occasional jobs, especially for people who often travel to do small jobs. You can also find portable compressors on the market that operate on 230V or 12V batteries.

Looking for help?

Contact Promptair & Electrical Pty Ltd for all your commercial and industrial maintenance and supply of air compressor, dryer, and even air filtration services. With Over 40 years in the field, trust their team to maintain and install your air compressors and accessories.

So, for all your compressed air piping needs, get in touch with an expert and let them help you with all your professional development needs. When it comes to compressed air piping, it is always better to call a professional instead of trying to do this yourself. So what are you waiting for? Give them a call for more information.

Pingback: Top 5 Things To Know About Compressors | Golocal business