Well preserved glass artifacts showcase ancient civilization’s successful attempts to make glass. Today, glass is a valuable material that serves many practical purposes.

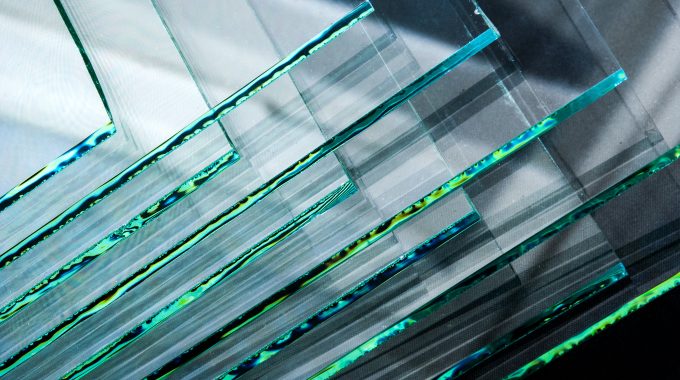

So much was discussed about the history of glassmaking in the first article and now, we shall consider some critical varieties of glass.

Some Important Varieties Of Glass

Let us discover some important varieties of glass.

Tough Glass

We generally think of glass as a brittle material. If a thrown or battled ball strikes a window, the pane is almost sure to break if we let it fall to the floor. In some cases, it is desirable to have brittle glass. For example, the glass used as a cover over the key in a fire alarm box is so brittle that a slight tap will shatter it; the key will then be accessible to the person who wishes to sound the alarm. For some purposes, however, we want tough glass.

As a material, glass is inherently very strong; freshly formed glass fibres are almost as strong as steel. Why is it easy, then, to shatter a windowpane with a comparatively light blow? To understand this problem, we must recognize the difference between tension and compression stresses. Tension stress is the force induced in an object when it is stretched; compression stress results from a squeezing force. If we push down at the middle of a rubber eraser, there will be tension stress at the under surface; it will stretch. There will be compression stress at the upper surface; it will contract.

Much the same thing happens when we apply a load to the centre of a bar of glass, supported at its ends. The under surface of the bar will tend to stretch and as it does so, it causes the upper surface to be compressed. Glass is relatively nonelastic. The under surface of the glass will bend just so much and no more; when the applied force exceeds the glass’s tensile strength, a crack will start. It will travel rapidly through the glass and will cause it to break.

The crack usually starts at some scratch or surface defect. Glaziers put this characteristic to good use when they cut window glass. They scratch the surface with a glass cutter and then apply pressure on the surface opposite the scratch; the glass will break along the scratch.

For many years, glass manufacturers like Tough Glass Worx obtained maximum strength in glass by carefully annealing it, thus removing internal stress. Today, the strength of glass is increased many times by controlled tempering –suddenly chilling after heating. The object of the chilling operation is to establish a uniform temperature difference between the glass surface and the interior at a high enough temperature so that any temporary stress in the glass may be released. On further cooling to room temperature, the hotter interior must cool more and hence contract more than the surface. The surface, therefore, develops high compressive stress, balanced by tensile stress in the inner part.

Let us again consider our bar of glass. If the underside of the bar is in compression to begin with, the first pressure exerted from above will merely remove some of this compressive stress. As more pressure is applied, the compressive stress in the underside lessens, until finally, there is tension stress instead of compression. If pressure still increases, it will exceed the tensile strength of the underside in time and the glass will break. But a good deal of pressure will have to be applied.

The tempering process has made it possible to manufacture much tougher glass than before. Tempered thin-walled drinking glasses are now more durable than the old heavy-walled tumblers; glass tableware will withstand severe restaurant service.

So, if you are looking for beautiful plate-glass doors without supporting frames that will be used in modern store fronts or automobile side and rear windows that can stand powerful blows without breaking, you can contact Tough Glass Worx today!